Drive-in / Drive-thru

Drive-in / Drive-thru

Static storage system - Drive-in / Drive-thru

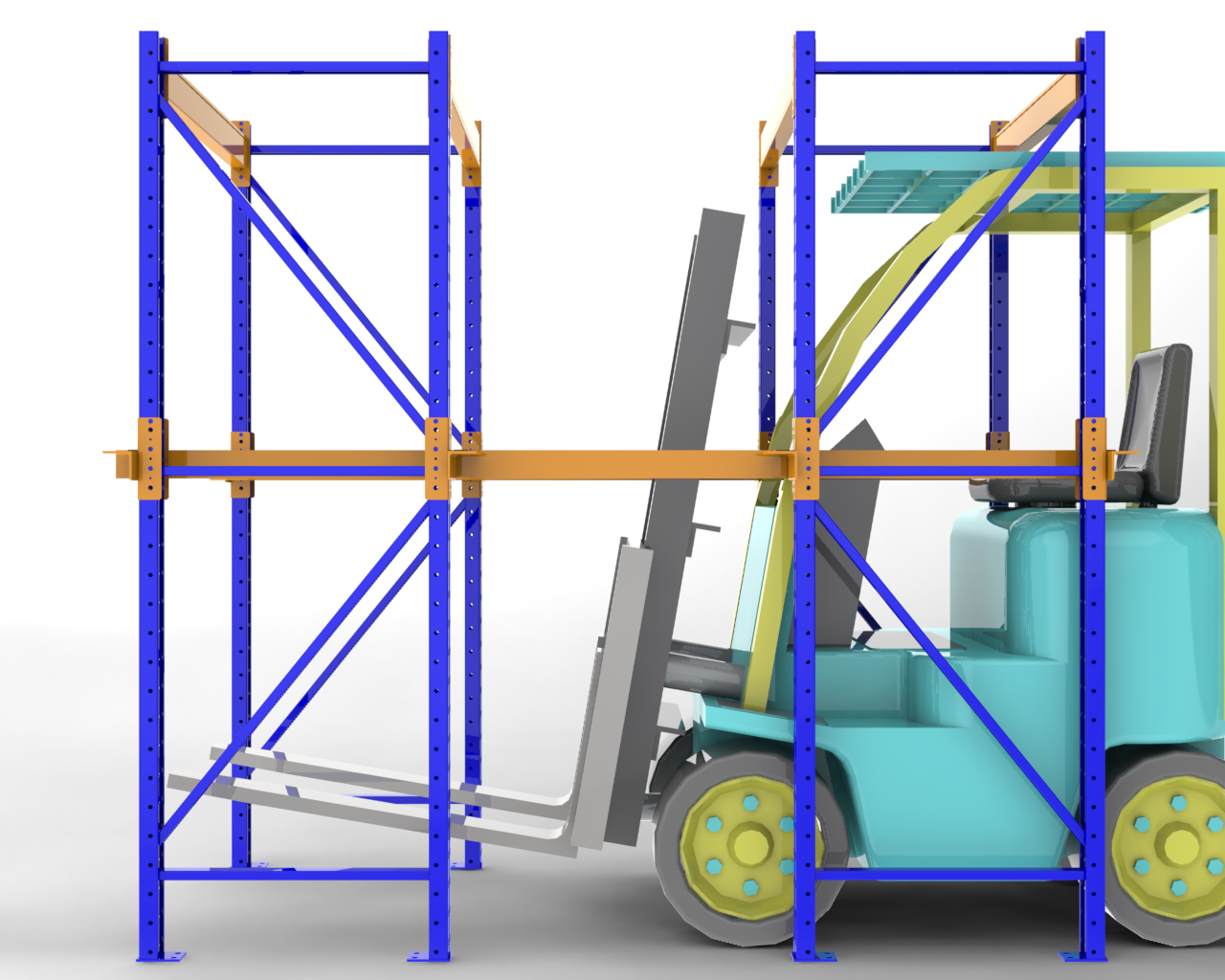

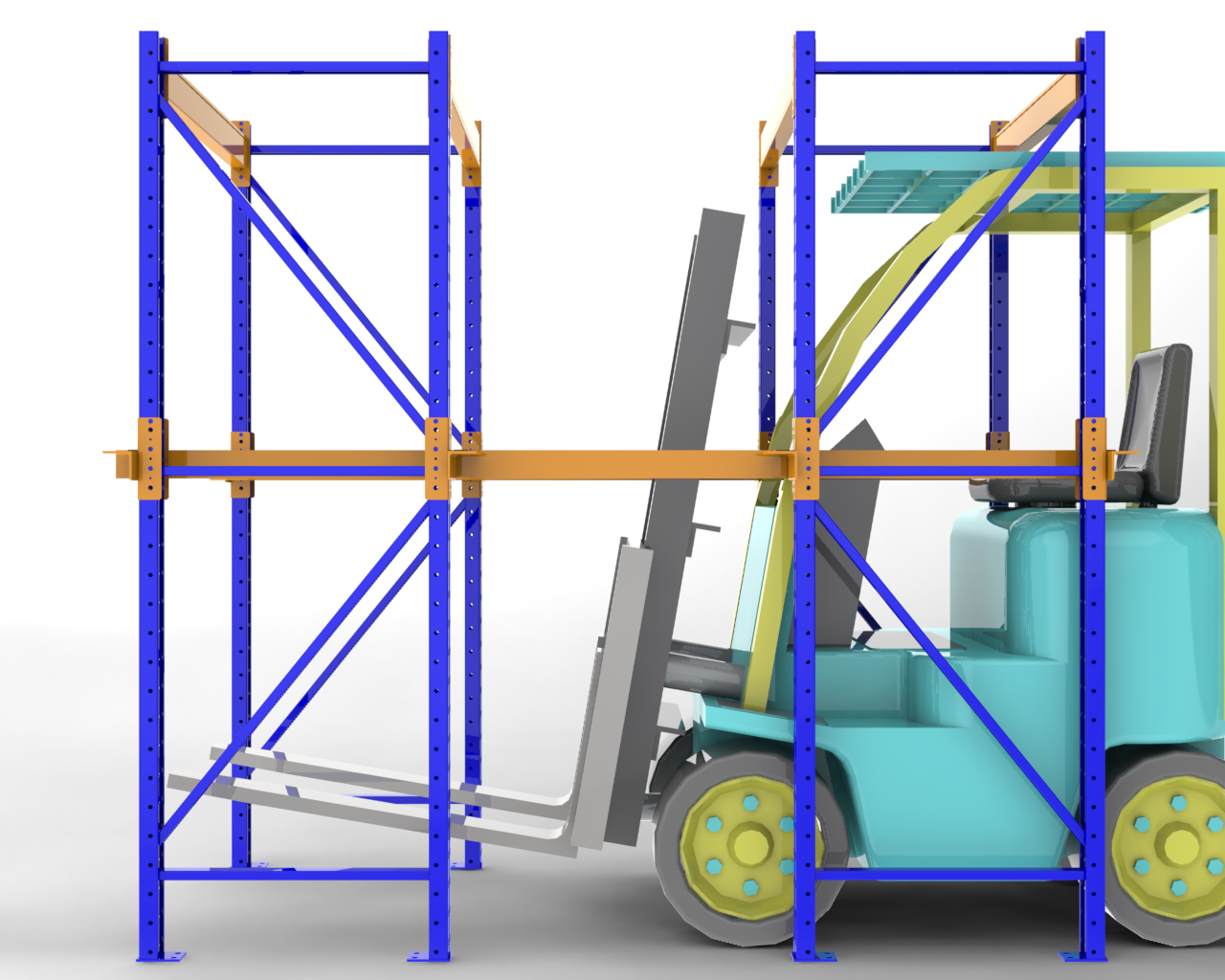

This system is a good compromise when you want to maximize the density of a warehouse. It makes it possible to increase the density considerably compared to the simple pallet rack. It is possible to have tunnels open on both sides (drive-thru) or on one side (drive-in). The drive-thru allows better accessibility and rotation of stocks.

Drive-in / Drive-thru

The drive-in/thru static system consists of supporting the pallets by the corners (without beams) using rails allowing the forklift to go inside the structure. The major advantage is to be able to store a large number of pallets in a small space.

Drive-in systems are FILO (first in, last out), while drive-thru are FIFO (first in, first out).

Main features of these systems

- Low cost system compared to the volume of pallets that can be stored.

- The truck must enter the tunnels in order to deposit the pallets.

- Selectivity less important since several pallets must be deposited one after the other.

- Less inventory turnover than for dynamic accumulation systems.

- The double-sided static accumulation rack allows for better inventory turnover.

- Type of system: first in, last out.

Main features of these systems

- Low cost system compared to the volume of pallets that can be stored.

- The truck must enter the tunnels in order to deposit the pallets.

- Selectivity less important since several pallets must be deposited one after the other.

- Less inventory turnover than for dynamic accumulation systems.

- The double-sided static accumulation rack allows for better inventory turnover.

- Type of system: first in, last out.

_1.jpg)