Single & Double deep

Single & double deep

Static storage system - single and double deep

Static systems are systems in which the pallets, once deposited, remain motionless.

Of all the systems, single-depth racking systems are the most popular and widespread.

Single deep

.JPG)

The most common and least expensive system: it consists of placing the pallets in single row or back-to-back configuration.

Double deep

Requiring a double deep reach truck, this system allows to store pallets two rows deep instead of one, increasing the number of pallets accessible from the aisle.

Single deep

.JPG)

The most common and least expensive system: it consists of placing the pallets in single row or back-to-back configuration.

Double deep

Requiring a double deep reach truck, this system allows to store pallets two rows deep instead of one, increasing the number of pallets accessible from the aisle.

Main features of these systems

- High selectivity of products. The trolley has access to all pallets in single depth.

- Possible use of the full height of the warehouse compared to a warehouse without racking.

- Need a trolley with retractable forks to access the second pallet, in the case of the double depth system. This same lift can be used in single-deep operations.

- Easily adjustable and interchangeable according to your types of operations.

- In the case of double depth, the storage capacity can increase by one third, depending on the layout of the warehouse.

- Narrow aisle trolleys available on the market can increase your storage by 20 to 30% by reducing the width of the aisles.

Main features of these systems

- High selectivity of products. The trolley has access to all pallets in single depth.

- Possible use of the full height of the warehouse compared to a warehouse without racking.

- Need a trolley with retractable forks to access the second pallet, in the case of the double depth system. This same lift can be used in single-deep operations.

- Easily adjustable and interchangeable according to your types of operations.

- In the case of double depth, the storage capacity can increase by one third, depending on the layout of the warehouse.

- Narrow aisle trolleys available on the market can increase your storage by 20 to 30% by reducing the width of the aisles.

For shorter lead times

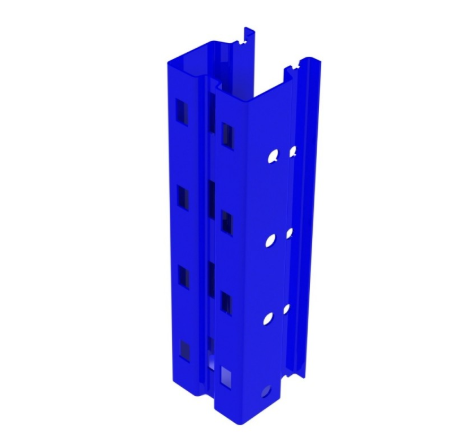

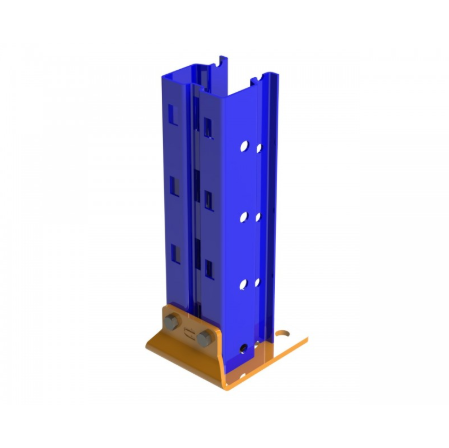

Go with bolted storage systems

See below for the advantages of bolted storage systems.

Lower transport costs

Fast and easy repairs

Versatility

For shorter lead times

Go with bolted storage systems

See below for the advantages of bolted storage systems.

_1.jpg)