Total:

$0.00

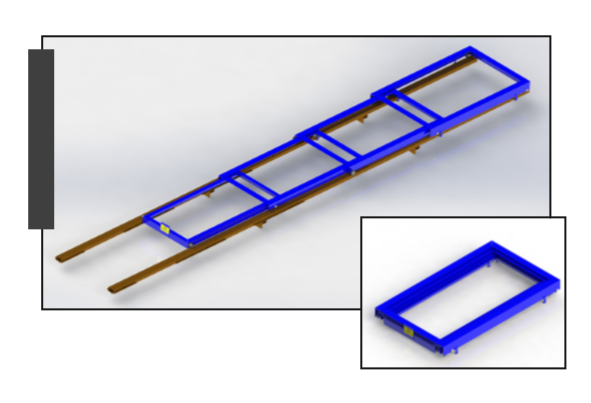

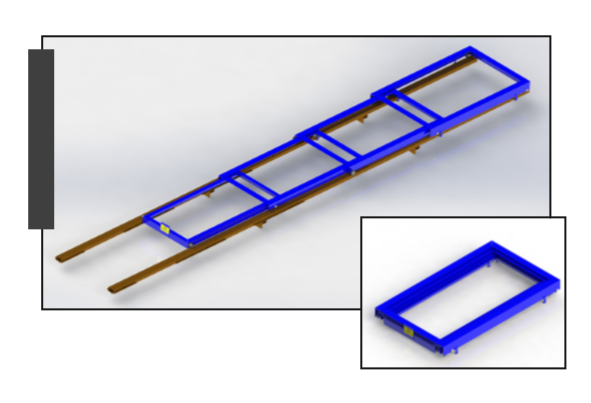

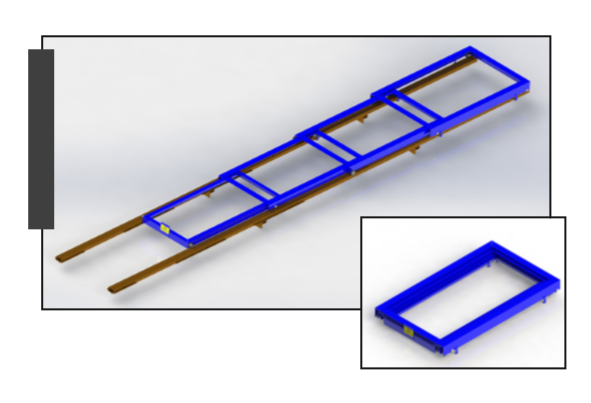

With a rail system inclined towards the driveway, gravity ensures that the pallets will always rest on the front beam. The first pallet is simply dropped on the first cart. For other pallets, the operator must push the pallet already in place to release the other carriages. To empty a line, one must progressively remove the pallets one by one. Gravity will take care of bringing the other pallets for picking.

Push back systems have carts mounted on wheels on which the pallet is deposited. Once the first pallet is in place, the forklift uses the second pallet to push the first one.

Push back systems are considered FILO (first in, last out). This system has greater storage density than drive-in systems (individual lines).